Acrylic

Acrylic Overview

Acrylic is a transparent thermoplastic often used as a shatter-proof alternative to glass. Acrylic is also know by the chemical name poly (methyl methacrylate). There are two basic types of acrylic: cast and extruded. Cast acrylic is made by casting the poly (methyl methacrylate) resin into a mold or onto a moving steel belt to form sheets. Cast acrylic is ideal for laser engraving because it creates a frosted surface. Common trade names for cast acrylic are Lucite™, Acrylite™, Shinkolite™A and Hesa™-Glas. Extruded acrylic is made by forcing the poly(methyl methacrylate) resin between a set of steel dies to form a continuous sheet, which is then cut into individual sheets. Extruded acrylic is ideal for laser cutting because it forms a flame polished edge during the laser cutting process. Common trade names for extruded acrylic are Deglas™, Homalite™, Optix™FG and Solatuf™.

Applicable Laser Processes for Acrylic

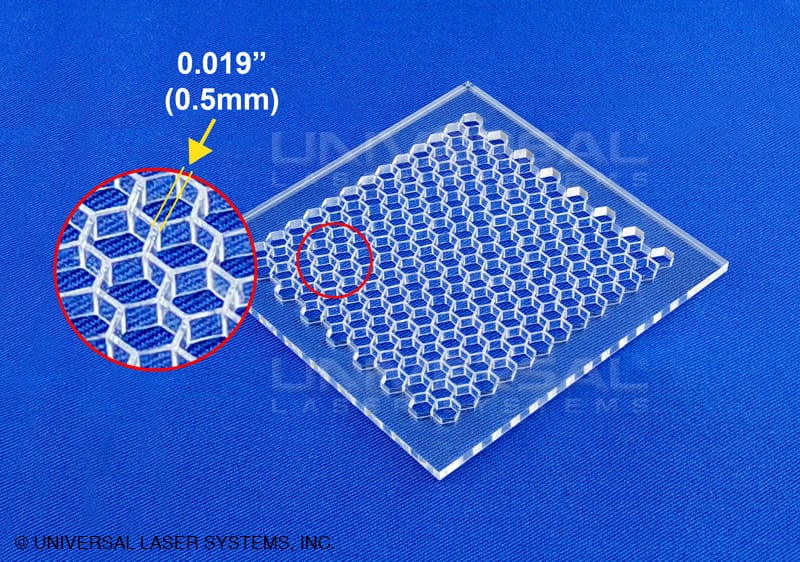

Laser Cutting

Laser Marking

Laser Engraving