SuperSpeed™ Technology

SuperSpeed™ technology offers customers the unique ability to drastically improve laser system productivity in laser engraving and marking. This patented technology was designed from the ground up to benefit the customer. Our SuperSpeed technology:

- Improves Laser Material Processing Throughput

- Improves Reliability and Uptime

- Provides Ultimate Laser Material Processing Flexibility

- Enables Additional Resolutions

- Is Easy to Use

How SuperSpeed Works

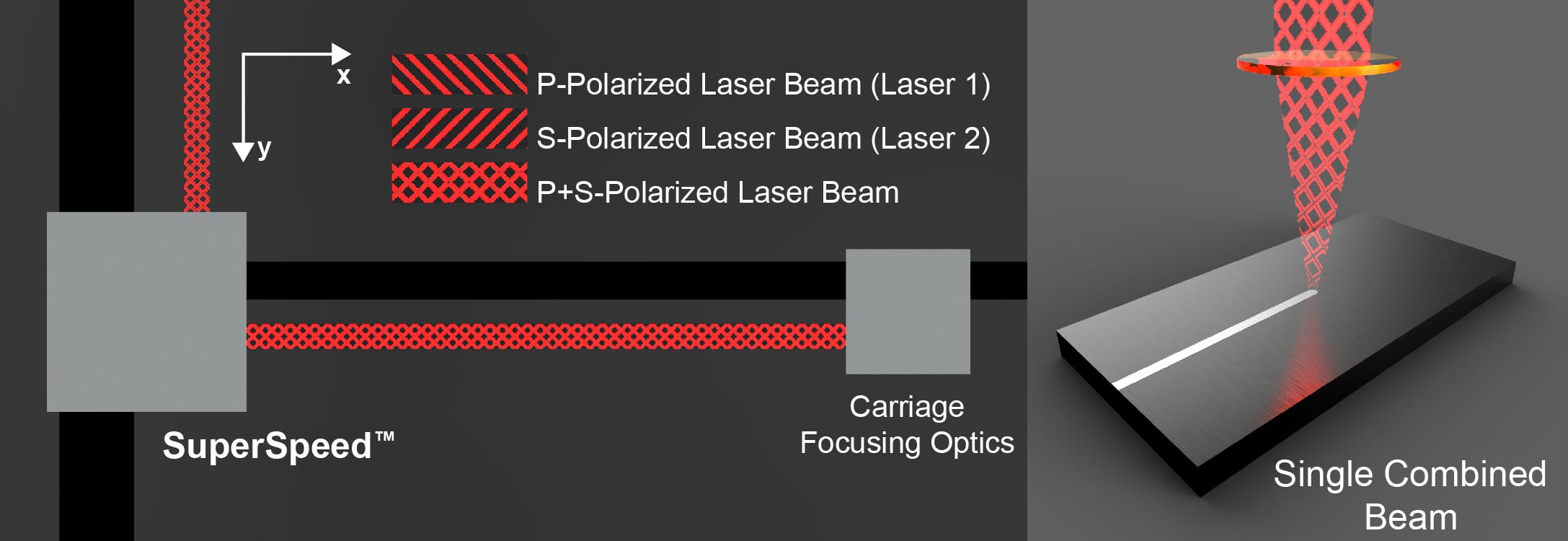

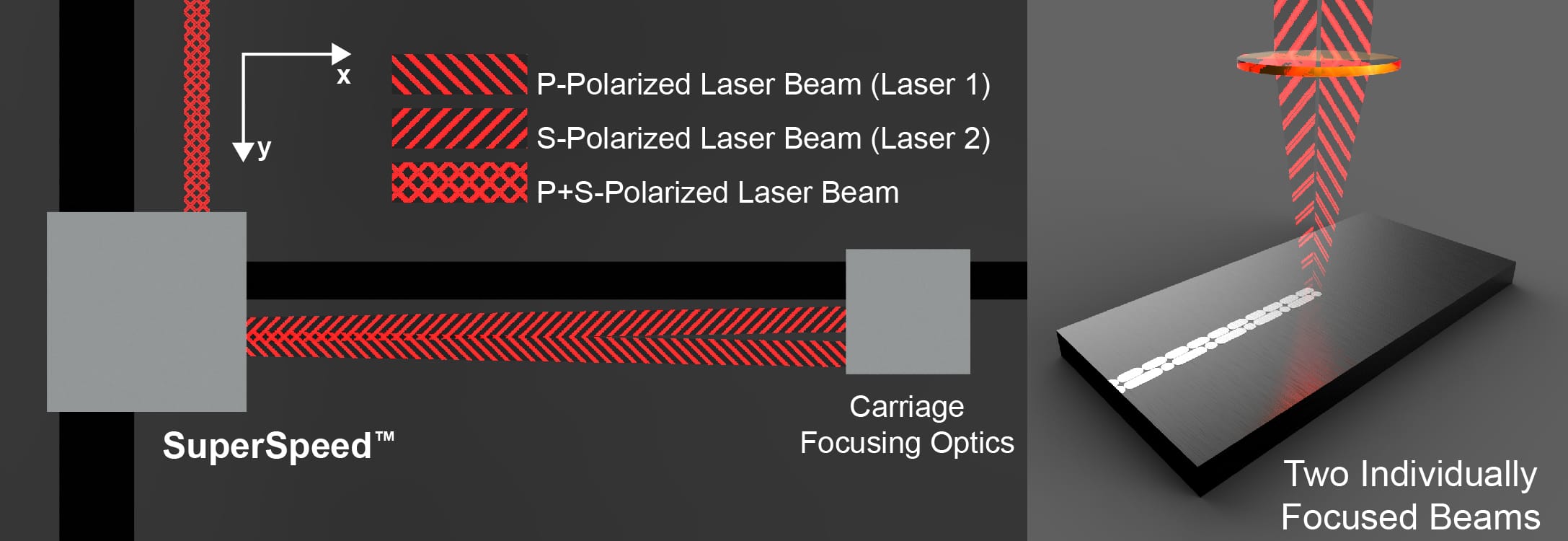

When a laser platform is equipped with two CO2 lasers of the same power, the combining optics result in one S-polarized beam and the other P-polarized. The SuperSpeed component uses this difference in polarization to independently control the focusing location of each laser. This is accomplished by placing an optical system containing a Thin Film Polarizer (TFP) in the beam path. The TFP allows the P-polarized laser to pass through transparently, while reflecting the S-polarized beam. A precision actuator is attached to a mechanical linkage, which controls the angle between the two beams. The focusing optics in the carriage focuses each of these beams to a slightly different location within the processing field.

SuperSpeed technology rotates the optical elements to angle the beams relative to one another. This causes each beam to focus to a slightly different location within the processing area. The more the optical elements rotate, the larger the separation between focusing locations. This is the configuration of SuperSpeed technology in raster mode.

SuperSpeed technology rotates the optical elements to angle the beams relative to one another. This causes each beam to focus to a slightly different location within the processing area. The more the optical elements rotate, the larger the separation between focusing locations. This is the configuration of SuperSpeed technology in raster mode.

Improves Laser Material Processing Throughput

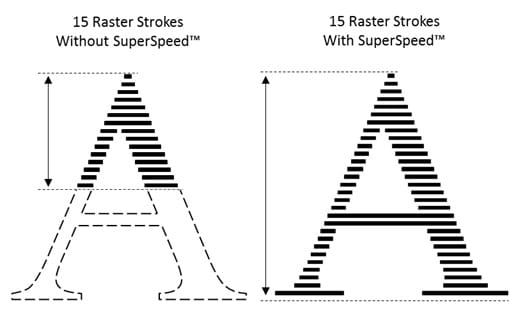

In raster mode, the carriage is moved bi-directionally along the x-axis while the laser is modulated to laser engrave or mark the material. Typical laser systems (also known as laser cutters, laser engravers, or laser markers) focus the laser energy to a single point, causing the material to be processed one line at a time. This is also true for single beam systems that use multiple lasers – all of the laser’s energy is limited to focusing on a single point. The SuperSpeed technology module overcomes this limitation by producing two focal spots – one for each laser beam. This means that the laser system can deliver two raster lines at a time, dramatically improving system productivity.

SuperSpeed technology is unique to Universal Laser Systems. The only way to substantially improve throughput with single beam laser systems without SuperSpeed is to purchase multiple systems. This increases systems costs as well as required floor space.

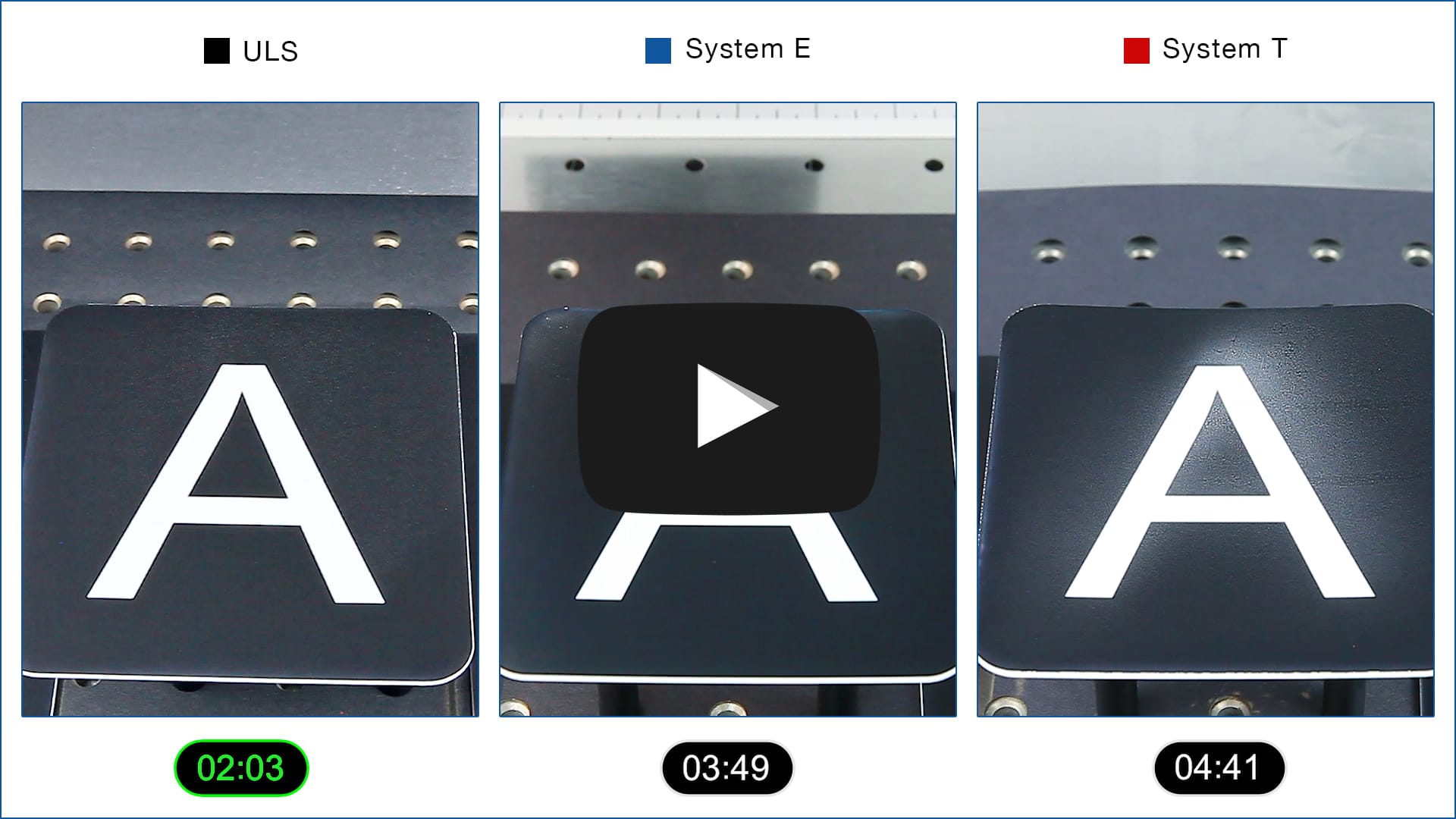

Over the past several years, laser system manufacturers have been competing with one another for faster and faster raster speeds. On the surface, this seems like a logical progression – faster raster speed means higher throughput, right? In reality, the situation is much more complex and often neglects the quality repercussions of higher top speeds.

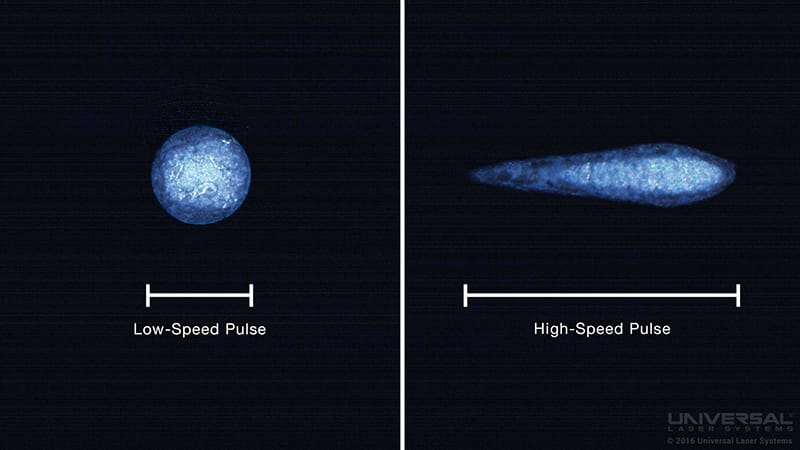

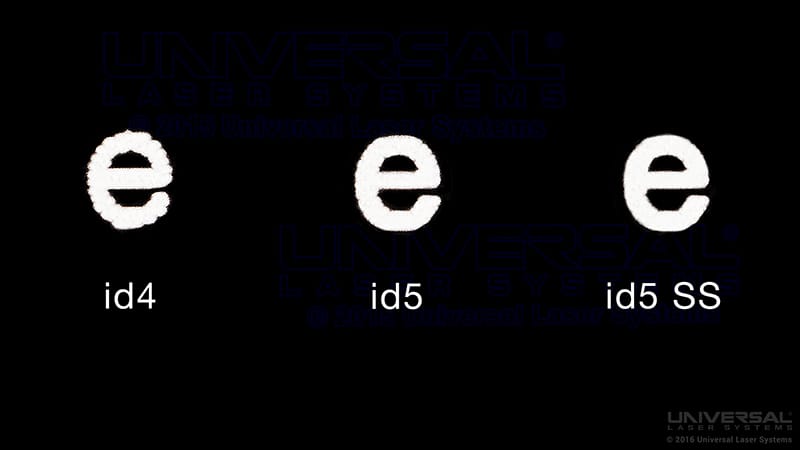

All CO2 lasers are limited by the rate at which pulses can be dispensed. At high raster speeds, CO2 lasers have a difficult time keeping up with the motion leading to laser pulses, which are spread over the x-axis lowering the energy density. This substantially decreases the quality of raster processes by producing an artificial blurring effect.

SuperSpeed technology allows the laser system to have very high throughput without this blurring effect, resulting in images that can be produced rapidly while maintaining a high degree of quality.

Improves Reliability and Uptime

In addition to all of the performance and quality benefits, SuperSpeed technology also increases system life and reduces maintenance costs. This is because the majority of service requests come from components such as bearings, pulleys, belts, and wheels – all components associated with the motion of the carriage. When using SuperSpeed technology, the carriage is able to skip every other line and process two raster lines in one stroke, thereby reducing mechanical wear by half. This decreases scheduled maintenance, driving down service costs and increasing laser system uptime.

Provides Ultimate Laser Material Processing Flexibility

Some materials respond better to higher image densities, while others exhibit processing benefits at lower image densities. SuperSpeed technology allows the image density to be adjusted without any hardware modification. SuperSpeed technology can also realign both beams to be on top of one another for vector marking and cutting. This brings the combined power of both lasers to a single location – maximizing vector cutting and marking throughput. All of the adjustments happen automatically and without user intervention.

SuperSpeed technology also enables unique processing capabilities through polarization. The user can select the amount of power being delivered by the S- and P-polarized lasers for both raster and vector processes. In vector processing, using both components will result in marks and cuts which have equal dimensions along both the x and y axes. Thinner marks can be made in one direction by using only a single laser source. In raster processing, the material can be modified by alternating P- and S-polarization marks to create interesting visual and physical effects.

Enables Additional Resolutions

SuperSpeed technology also enables ULS laser cutting, engraving, and marking machines to process materials with additional resolutions that are not otherwise possible. This has both quality and throughput advantages for some materials. Microsurface plastics, for example, are specially designed to display high contrast marks when laser-processed. Raster marking these plastics on a non-SuperSpeed laser system using lower resolutions leaves noticeable bands between each raster line. Higher resolutions leave no such marks but process the material more slowly. With SuperSpeed technology, there is an additional resolution that leaves no bands between raster marks but doesn’t make as many raster lines as the higher-resolution mentioned above. This reduced number of raster lines coupled with the throughput doubling of SuperSpeed technology results in an enormous benefit.

Is Easy To Use

The setup process for SuperSpeed technology is handled at the factory. During operation, the user simply selects whether or not to process using SuperSpeed technology via a checkbox. The module will automatically combine both beams for vector processes or deflect each beam the correct amount for each image density. The entire process is very simple. If adjustments are required, the software provides several easy-to-use tools to expedite the process.