Laser Cutting

Laser cutting is the complete removal and separation of material from the top surface to the bottom surface along a designated path.

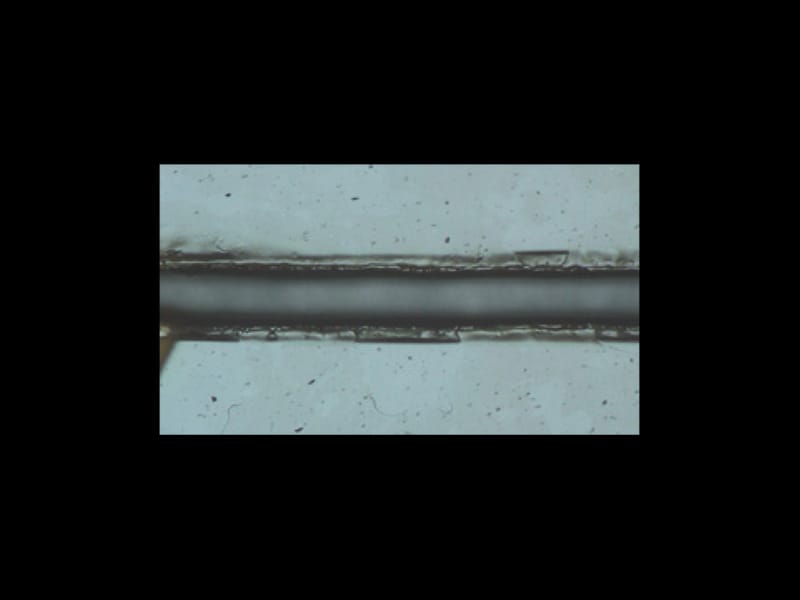

3M Protection Films are straightforward to cut using DLMP technology. The edges created by laser cutting will show no discoloration. Vapor deposition onto adjacent surfaces may occur; however, this can be mitigated using several methods.

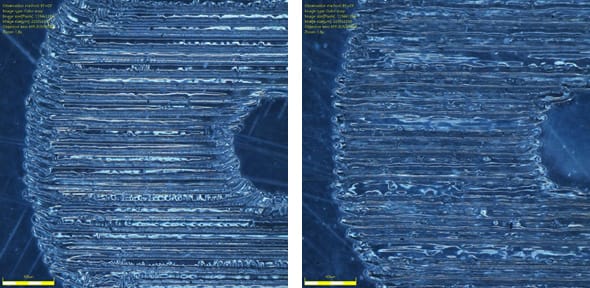

As mentioned, 9.3 μm energy is more efficiently absorbed by PET, the base material in 3M Protection Films. This results in cleaner ablation, with less HAZ and melt-back. The example on the left shows shows a cut made with made with a 9.3 μm laser, and the example on the right shows a 10.6 μm laser magnified at 132x.

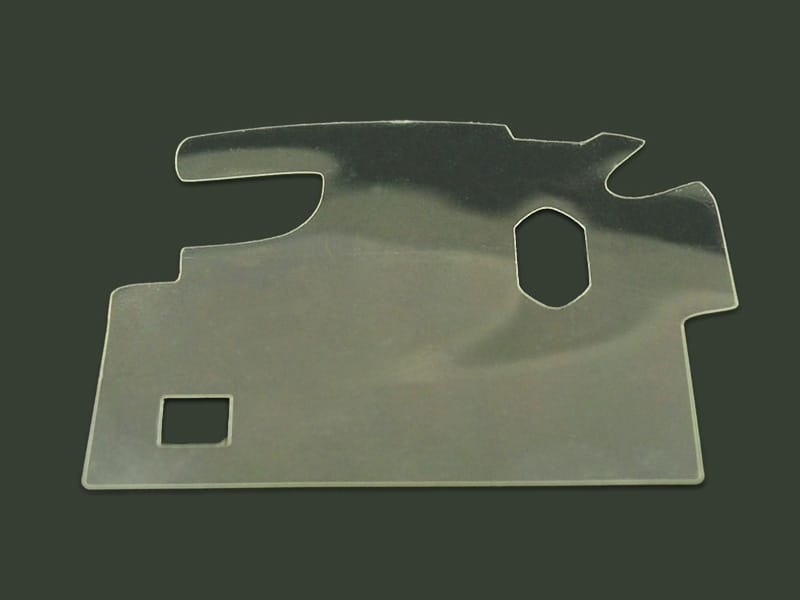

Finally, this example shows a simple shape cut from a sheet of 3M Glossy LR Protection Film GLR320. The basic capability shown can be extended to nearly any shape, even complex and closely-spaced cuts.