Laser Processing of Henkel Bergquist™ Sil-Pad A2000

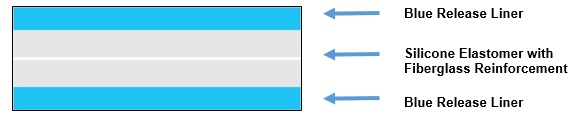

Bergquist™ Sil-Pad A2000 is part of a product line of other thermal gap pad materials including 400, 800, 900S, 980, 1100ST, 1200, A1500, 1500ST, 2000, K-4, K-6, and K-10. The Bergquist Sil-Pad A2000 sheet product selected for testing consists of three layers totaling 685µm thick. The center layer is a 381µm thick silicone elastomer reinforced with fiberglass strands. On each side of the elastomer there is a blue liner measuring 152µm thick. A diagram depicting Bergquist Sil-Pad A2000 is shown in Figure 1.

Figure 1. Henkel Bergquist Sil-Pad A2000 diagram illustrating the silicone elastomer layer (381µm) and the protective outer two blue release liners (152µm each).

Bergquist Sil-Pad A2000 is only suitable for laser cutting that produces even processed edges and minimal heat-affected zones without degrading the material’s physical properties. Universal Laser Systems MultiWave Hybrid™ technology makes it simple to process this material to a high degree of dimensional accuracy, with consistent processed edges, minimal heat affects, and virtually no material deformation during processing.

Laser Processing Notes

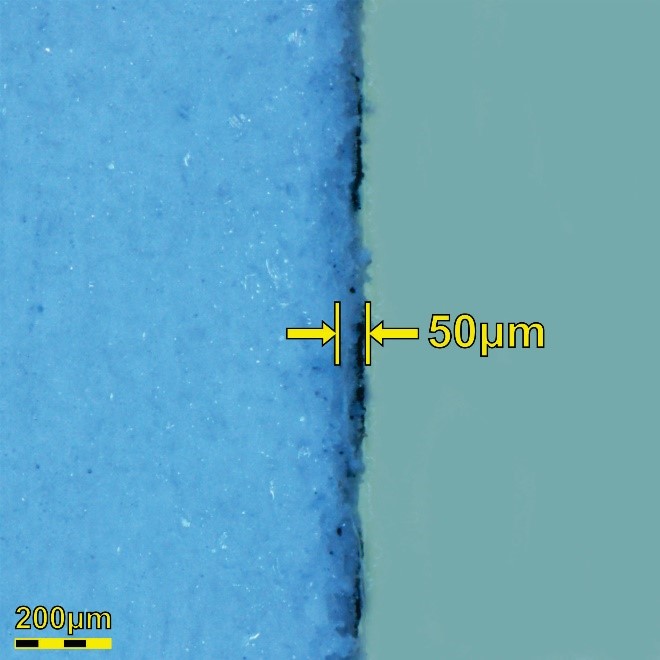

Bergquist Sil-Pad A2000 was tested to assess laser processing compatibility and to determine the best configuration of peak laser power and wavelength. The silicone elastomer in Bergquist Sil-Pad A2000 absorbs 9.3µm energy more efficiently than other wavelengths available from Universal Laser Systems. The fiberglass reinforcement strands inside the silicone absorb the 1.06µm wavelength most efficiently. The combination of 9.3µm and 1.06µm laser wavelengths in the MultiWave Hybrid system configuration, which combines the two wavelengths into one simultaneous beam, produces a consistent processed edge with minimal heat affects. The 1.06µm laser is able to cleave the fiberglass strands effectively and the 9.3µm laser ablates the silicone elastomer. In Figure 2 below, a microscopy image taken at 200x magnification shows the processed edge of Bergquist Sil-Pad A2000 processed with the top blue release liner removed.

Figure 2. Microscopy image (200x) of the laser-processed edge of Bergquist Sil-Pad A2000. The heat-affected zone measures 50µm.

Table 1. System Configuration Comparison

| System Configuration | Heat-Affected Zone | Process Characteristics | Post-Processing Requirements |

|---|---|---|---|

| MultiWave Hybrid 1.06µm and 9.3µm (Recommended) | Minimal heat-affected zone of approximately 50µm | In the MultiWave Hybrid configuration, the silicone is ablated by the 9.3µm laser, while the 1.06µm laser is simultaneously cleaving the fiberglass reinforcement along the edge, resulting in a cleaner more consistent result | Processing Bergquist Sil-Pad A2000 with either the MultiWave Hybrid configuration or the 1.06µm fiber laser configuration produces a nominal amount of surface debris along the processed path that can be removed with light abrasion and a solvent such as isopropyl alcohol |

| MultiWave Hybrid 1.06µm and 10.6µm | Minimal heat-affected zone of approximately 70µm | This configuration results in an increased heat-affected zone and less consistency along the processed edge when compared to the MultiWave Hybrid configuration comprised of a 9.3µm laser and 1.06µm laser source | |

| 1.06µm | Increased heat-affected zone compared to 9.3µm wavelength, approximately 70μm | This configuration results in an increased heat-affected zone and less consistency along the processed edge when compared to the MultiWave Hybrid 9.3µm and 1.06µm laser source configuration |

Figure 3. Comparison microscopy images (300x) of the processed edge resulting from MultiWave Hybrid cutting with 1.06µm and 9.3µm lasers (left), MultiWave Hybrid cutting with 1.06µm and 10.6µm lasers (center), and cutting with the 1.06µm fiber laser alone (right). In all three images, the top blue release liner has been removed prior to processing.

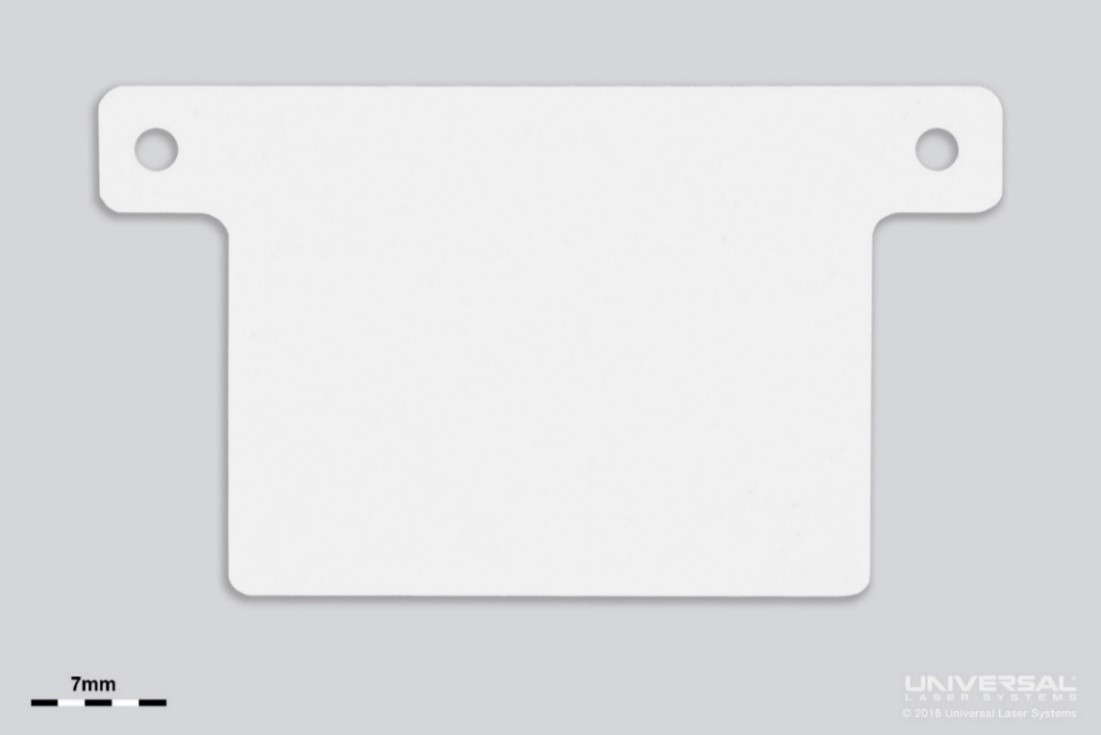

Henkel Bergquist Sil-Pad A2000 applications requiring fine geometry and intricate detail without degrading the material’s physical properties can be accomplished with Universal Laser Systems MultiWave Hybrid technology. An example demonstrating the results of laser cutting Henkel Bergquist Sil-Pad A2000 using the recommended system configuration is shown in Figure 4.

Figure 4. Example of the fine geometry possible with laser processing of Bergquist Sil-Pad A2000. The top blue liner has been removed from this material prior to laser processing.

Henkel Bergquist Sil-Pad A2000 is suitable for laser processing and was extensively tested to determine the best process configuration. Through this testing, it was determined that laser processing is viable with this material and the use of Universal Laser Systems MultiWave Hybrid technology, with a combination of a 50 watt 1.06µm laser and a 75 watt 9.3µm laser, is the optimal configuration. Bergquist Sil-Pad A2000 efficiently absorbs the 1.06µm and 9.3µm laser energies to produce a processed edge that has a minimal heat-affected zone and almost no discoloration.