Laser Cutting

Laser cutting is the complete removal and separation of material from the top surface to the bottom surface along a designated path.

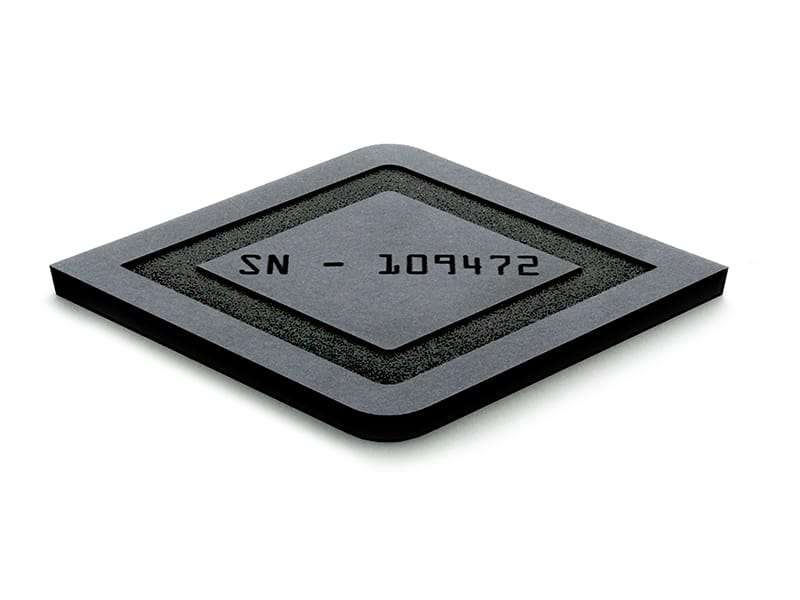

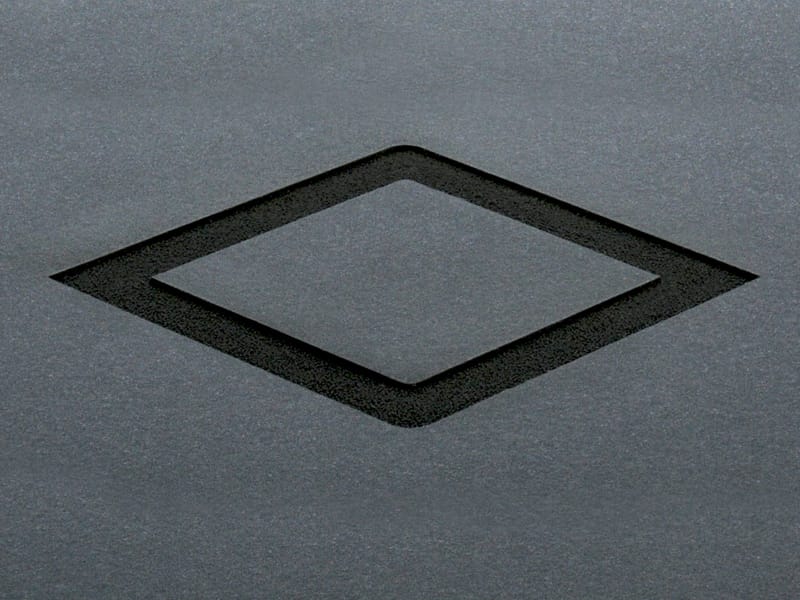

Due to its high service temperature and low density, 3M Polyurethane Foam ablates cleanly from the bulk material. The edges that result from laser cutting are smooth and free from discoloration sometimes associated with thermal processes. This is demonstrated in the folliowing example with a 0.25 inch (6.35mm) thick diamond shape laser cut from 3M Polyurethane Foam.

Laser cutting this product produces very little debris and can be used as-is in most cases. For thicker sections, a wet cloth may be used to wipe away any solids. The basic capability shown can be extended to nearly any shape, even complex and closely-spaced cuts.

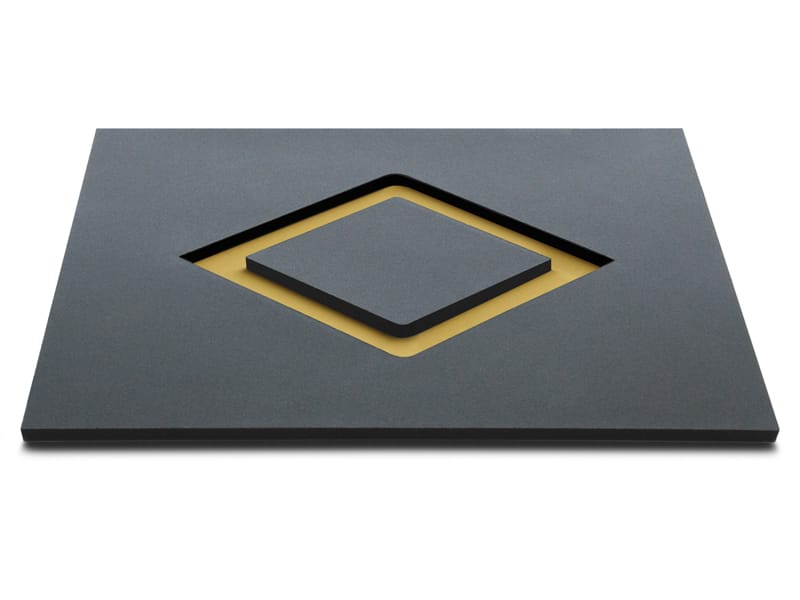

When used with an adhesive liner, partial cutting is also possible. Partial cutting is a type of selective cutting whereby the top layer of material is ablated through, but the bottom layer is left intact. This is possible because the laser can be precisely modulated over the entire work area. The next three images show an example of how a partial cutting process can be applied to 3M Polyurethane Foam. The foam and adhesive of the desired shape is peeled away while leaving the liner intact.