Laser Marking

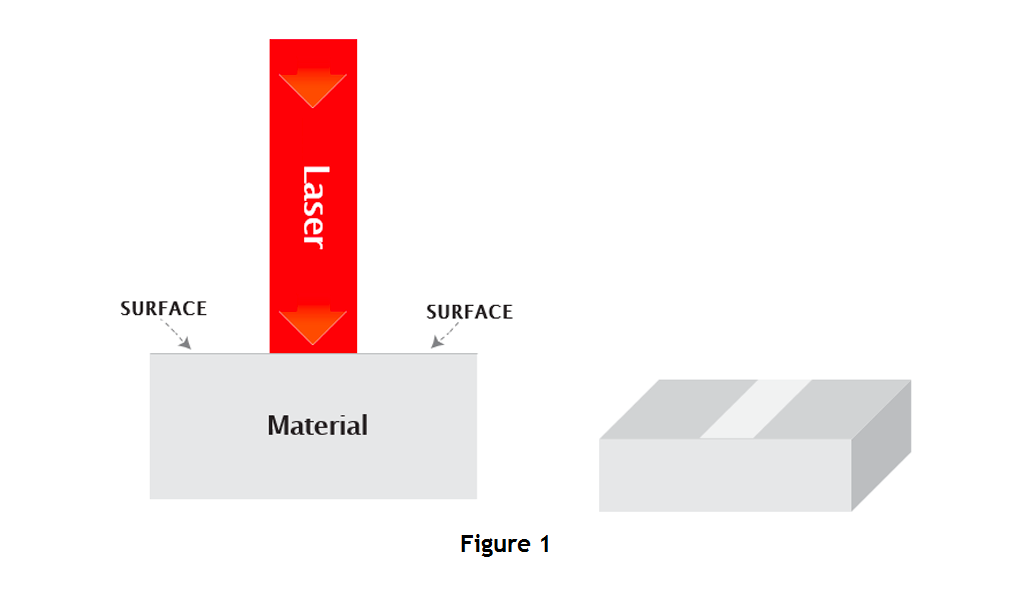

Laser marking is comprised of two distinct types. Laser marking removes material to create depth (laser depth marking) or modifies the material to change the color, contrast or reflectivity of the surface (laser surface marking). In general, laser marking is the production of human- and/or machine-readable identification or information on a material such as a barcode, date/lot code, serial number or part number. Other information items including logos, diagrams, illustrations and photographs can also be marked on a material. (See Figure 1 below.)

Most materials can be laser marked, but results will vary depending on the laser wavelength used.

Both 10.6 micron and 9.3 micron CO2 lasers are used for marking non-metal materials with depth, as well as for surface marking of some metals. Fiber lasers with a 1.06 micron wavelength are used for surface marking of many materials and surface or shallow depth marking of metal. Laser depth marking is sometimes referred to as laser engraving.

Learn more about why laser technology is an ideal tool for meeting tight tolerance specifications when used as a laser cutter and how laser technology enables distinctive design characteristics when used as a laser engraver or laser marker.