Automation Interface

The automation interface makes it possible to integrate ULS laser systems into automated manufacturing environments. Programmable inputs and event-driven outputs, combined with a powerful user interface, allow users to seamlessly adapt their laser systems to diverse automated applications. This ULS-exclusive option benefits users in the following ways:

- Comprehensive External Laser System Control

Initiate up to eight different laser system functions with programmable inputs. - Integrate External Devices into Laser Material Processing

Control or signal up to two external devices using event-driven, programmable outputs.

Comprehensive External Laser System Control

Controlling a ULS laser system in an automated manufacturing environment is accomplished through the optional Automation module.

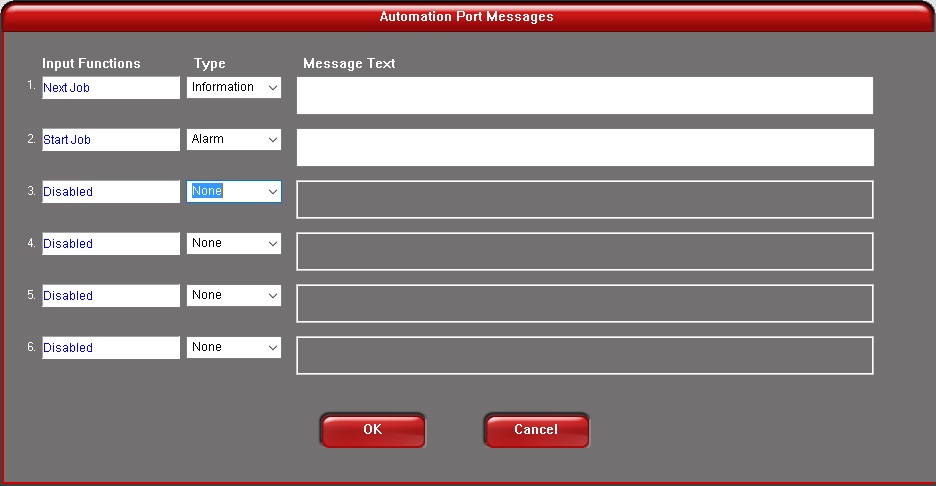

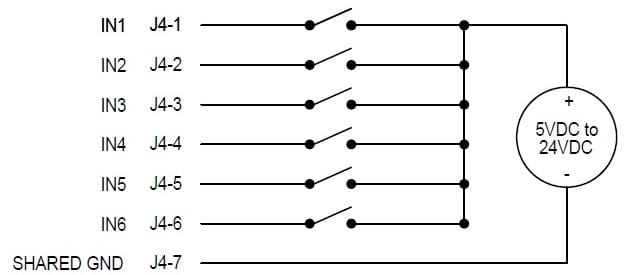

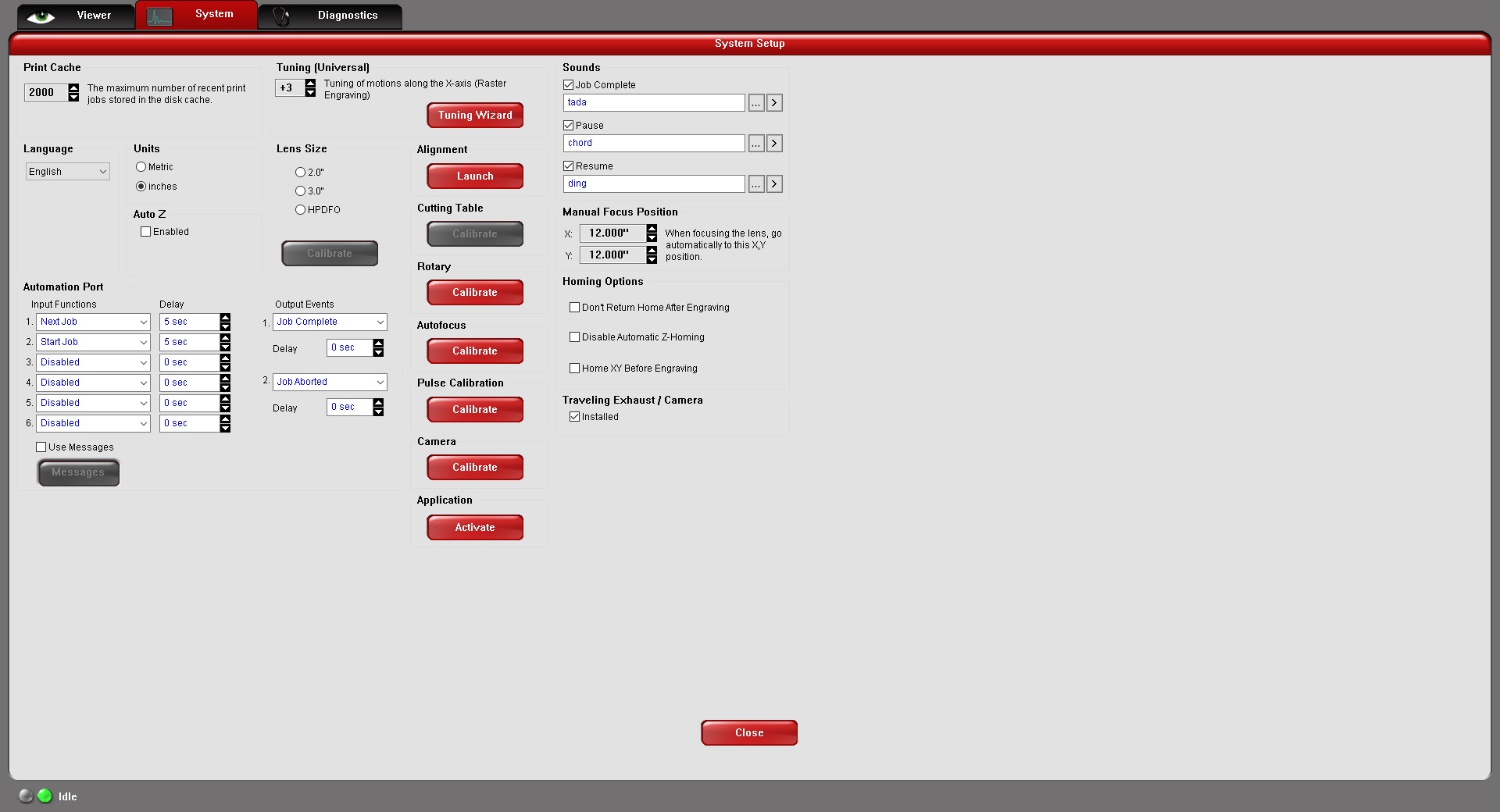

Six digital inputs are available via the Automation Control Panel accessed through the Universal Control Panel (UCP) or Laser System Manager (LSM). These inputs can be initiated through switches, relays, or digital logic signals from a PLC or microcontroller, providing users with the flexibility to control different laser system functions from diverse sources. The programmable inputs can be assigned to perform comprehensive control of major laser system functions as depicted below as well as displaying customized messages on the host computer’s screen. Function delays may be included to suit the user’s automation needs. This benefits users by allowing them to fully control their ULS laser system from other equipment, controllers, and through remote user input.

Integrate External Devices into Laser Material Processing

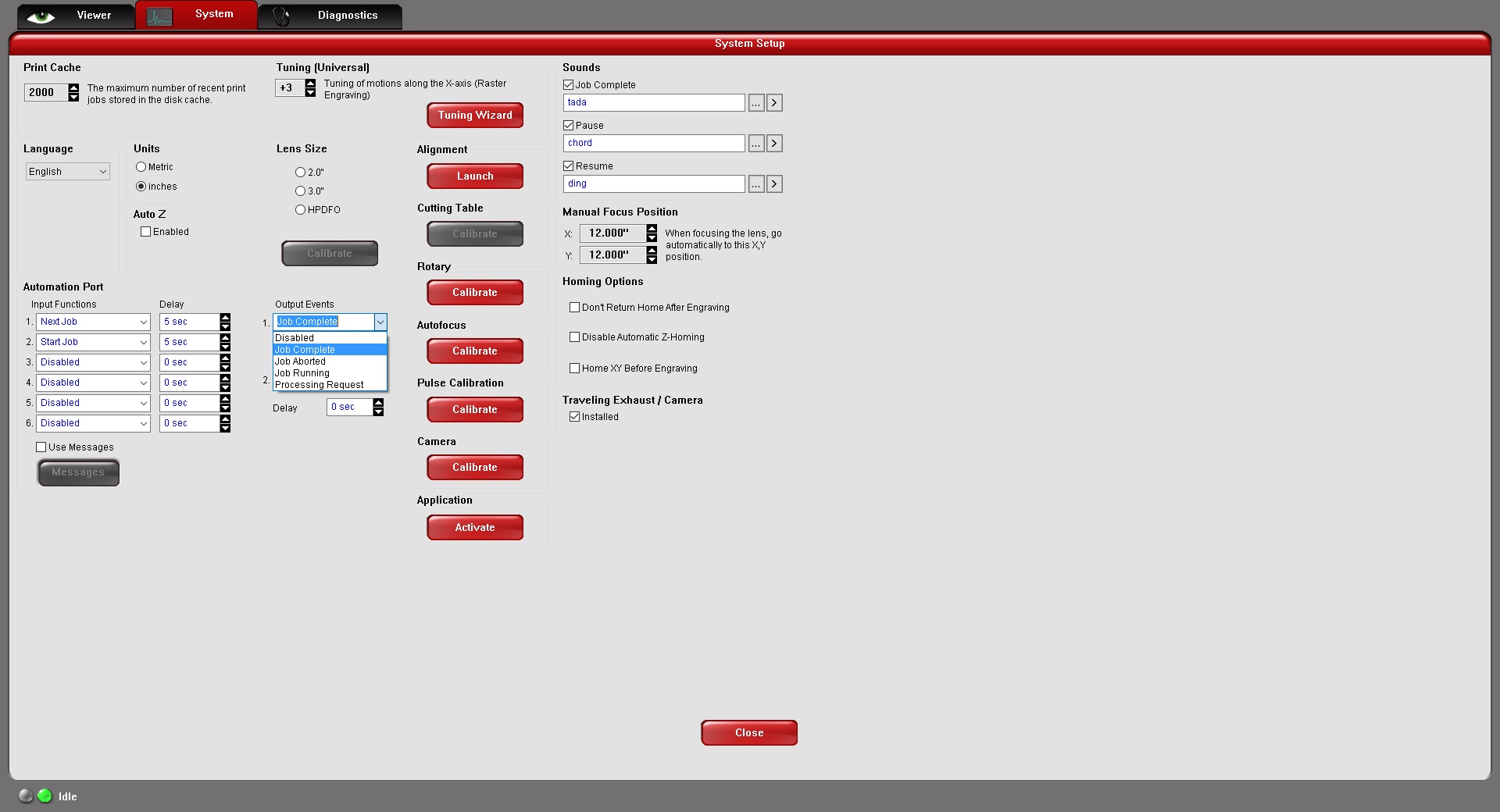

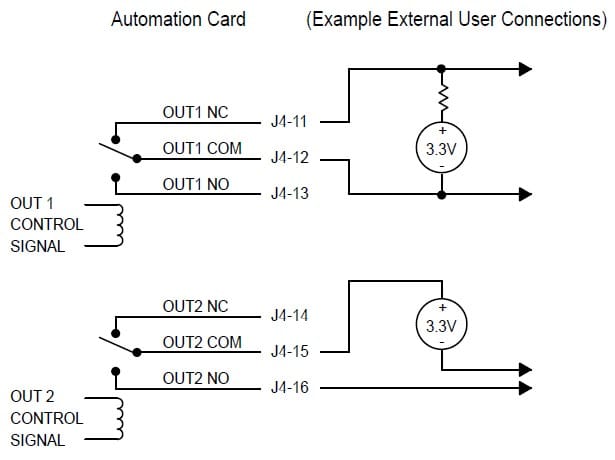

Controlling external devices that operate in conjunction with a ULS laser system is readily accomplished through the Output Event portion of the Automation Control Panel. The two outputs are driven by laser system events as depicted below.

Each output can provide a closed or open circuit, depending on the requirements of the device being controlled, allowing for a completely flexible device environment.

The Automation Interface benefits users by allowing them to control electro-mechanical devices such as air-movers, valves, compressors, signal lights, and audible alarms. The outputs can also be used as digital signals to PLCs or micro-controllers to initiate various complex control functions in the manufacturing cell such as indexing a conveyor belt and initiating a pick-and-place sequence.

The Automation Interface capabilities can be augmented with the ULS Class 4 Conversion Module in cases where direct access to the processing area of the laser system is desirable. Automated loading and unloading of parts and material can be accomplished without user intervention.