Direct File Import

ULS laser material processing systems are designed as a computer peripheral. Print drivers are supplied with the laser system to allow users to print design files making them broadly compatible with a wide selection of software from graphic design to CAD/CAM. However, there can be certain limitations in the printing process, mostly related to communication. To overcome these limitations, ULS offers a direct file import option that enables users to import certain graphic file formats (PDF/DXF/G-Code) directly into the laser system control software bypassing the printing process. The Direct File Import option provides the following benefits to the user:

- Improved Flexibility and Ease of Use

Allows the user to import standard design file interchange formats, reducing the time and potential errors in setting up and learning third party graphic software. - Improvement in Vector Processing Quality

Eliminates down sampling of vector data that occurs during the traditional printing process resulting in the highest possible fidelity to the original design file. Down sampling is the process of reducing the sampling rate of a signal. This is usually done to reduce the data rate or the size of the data. - Improved Cross Platform Compatibility

Designs created on Mac and other platforms can be saved in a common interchange format and imported into the laser system control software without the need to open and reprint the original files on a Windows PC.

Improved Flexibility and Ease of Use

Users can import DXF and PDF file formats directly into the control software for any ULS laser system. In addition to these formats ULTRA users can import G-code files.

DXF File Format

The DXF import process supports vectors only and will parse a DXF file for all vector data. Color assignments in the DXF file format are preserved and used to assign process type and settings to each vector path allowing users to assign different processes and settings to different colored vector paths in the design file. Users can specify scale and also force the design to the center of the field to eliminate issues with coordinate systems in the DXF file format. High fidelity vector data is passed to the laser system control software allowing for a high level of accuracy when working with 2D CAD data.

PDF File Format

The PDF file format supports both raster and vector data. Color assignments in the PDF file format are preserved and used to assign process type and settings to both raster and vector data allowing users to assign different processes and settings to different colored elements in the design file. Support for both raster and vector data makes the PDF file format very versatile for importing designs for laser engraving, marking and cutting.

G-Code File Format (ULTRA)

The G-code format contains instructions typically sent to CNC machine tools for vector cutting and machining processes. The G-code importer will extract the vector data from the G-code file for vector cutting and marking on a laser system. This format allows users to leverage any investment they may have in CAM software for CNC machining and use the same process to create design files for laser material processing.

The wide variety of file formats described above give users flexibility to take advantage of a multitude of different types of design software available today from graphics software and 2D CAD software to the latest solid modeling software and even machine tool data. The import process also allows laser system operators to take advantage of the common interchange formats to process designs created by others on software the operator may not own or be trained to use. Direct File import allows laser processing to be more seamlessly integrated into an organization's workflow and reduces disruption required for software training.

Improvement in Vector Processing Quality

Because the print process is controlled by the operating system of the PC, this process has several limitations for users of laser material processing systems. The operating system requires the user to select a fixed resolution for the print process. This resolution is used to control the raster process and defines the number of lines per inch for the raster engraving and marking. Users choose different resolutions based on throughput and image quality needed. Lower resolutions reduce the number of raster passes needed to engrave or mark the pattern which increases throughput. However, lower resolutions adversely affect the quality of vector cut and mark data without improving vector throughput.

Using the Direct File Import option means the resolution of raster data can be independent of the resolution of vector data. When design files are imported, the user can select an image resolution for the raster data to control throughput for raster imaging independent of vector resolution. The import engine can apply the selected resolution to all raster data and simultaneously maintain the highest fidelity for the vector data. This benefits the user by providing the best possible vector quality for laser cutting and marking while optimizing throughput of raster data. No compromises are necessary.

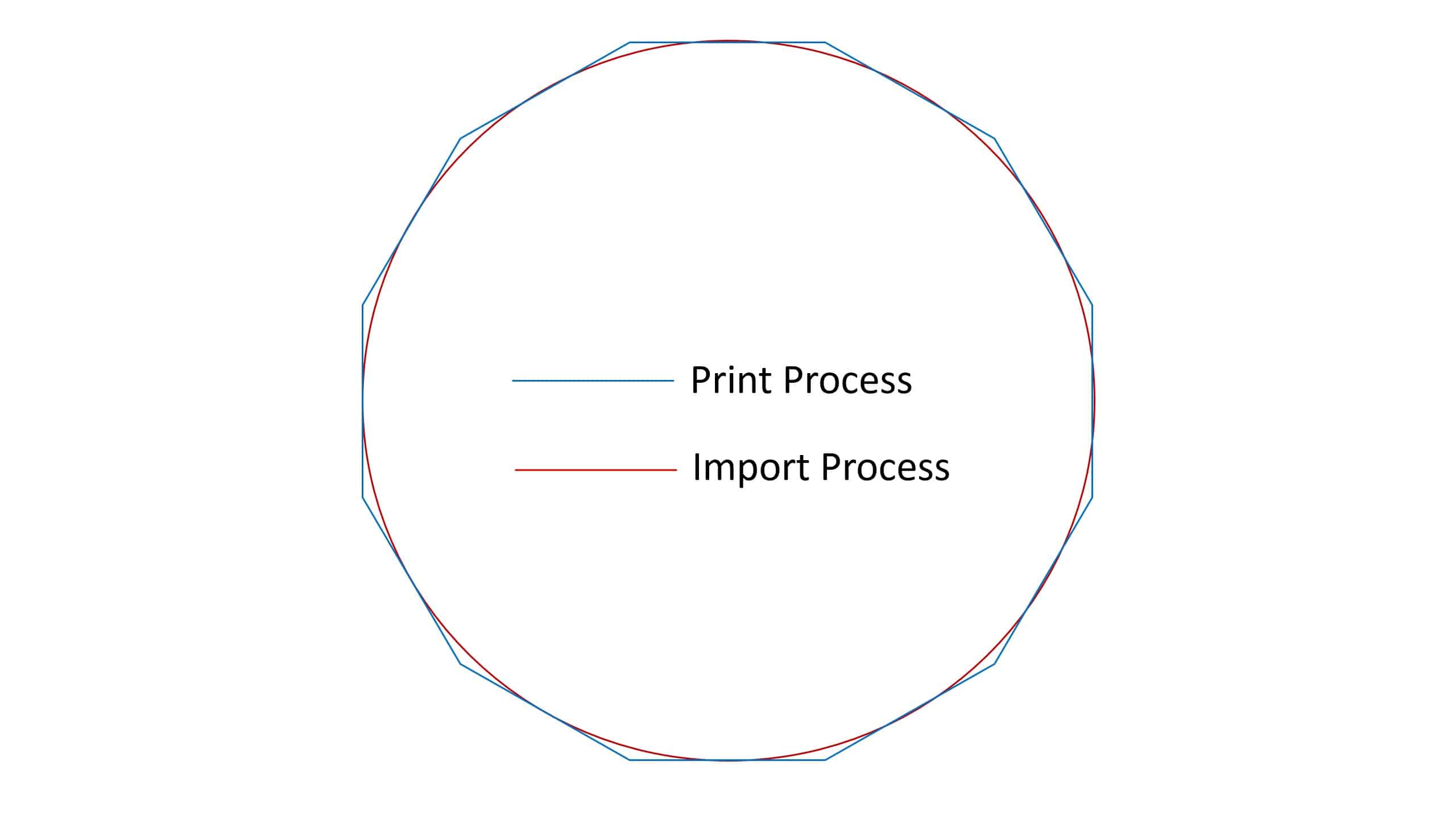

An additional limitation to printing is that the operating system print engine renders curves, splines, and other non-line elements into patterns of small line segments called polylines. A circle for example might be rendered with a number of small line segments forming a polygon as seen in the illustration below. The import process overcomes this limitation by passing the true circle, arc and curve data directly to the laser system control software, allowing the laser system to produce higher fidelity marking and engraving results which improves laser material processing quality for the user.

Improved Cross Platform Compatibility

Another benefit of the Direct File Import option is that it allows users to create artwork on non-Windows based PCs such as Mac or Linux based PCs. Users can use design software on the operating system of their choice without needing to reopen the design file on a Windows PC and print to the laser system. The user simply saves the design file to one of the supported interchange formats and imports it directly into the control software. This benefits the user by making creation of designs more cross-platform friendly so users can design for laser material processing using the computer and operating system with which they are most comfortable.