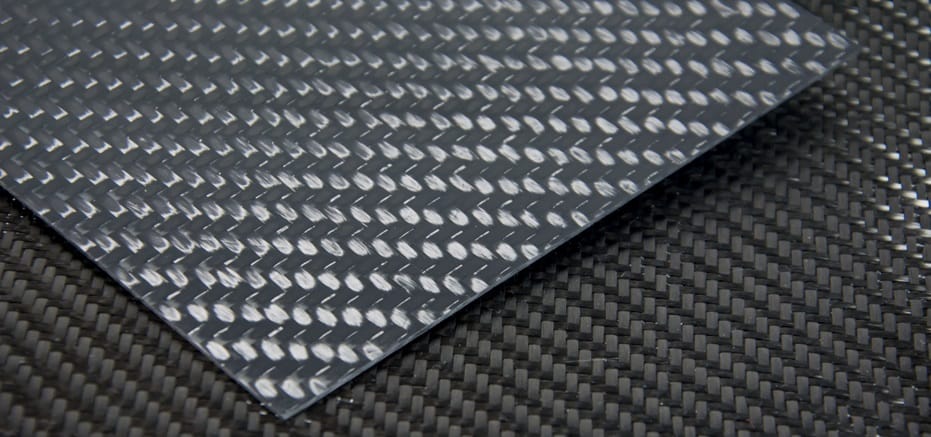

Composites

Composites are formed by combining two or more materials with different properties to form a new material (the composite) with properties that are superior to those of the individual components. For example, carbon fiber reinforcing material is embedded into an epoxy matrix material to form a strong, lightweight structural composite. The carbon fiber by itself is not rigid enough to be used as a structural material, and the epoxy by itself is not sufficiently strong. Most composites can be processed by laser cutting, engraving, and marking.

Types of Composite Materials

Types of Laser Processes

Lasers are playing an ever expanding role in material processing, from new product development to high volume manufacturing. For all laser processes, the energy of a laser beam interacts with a material to transform it in some way. Each transformation (or laser process) is controlled by precisely regulating the wavelength, power, duty cycle and repetition rate of the laser beam. These laser processes include the following:All materials have unique characteristics that dictate how the laser beam interacts and consequently modifies the material. This is true whether one uses the laser system as a "laser cutter", "laser engraver", or "laser marker". The most common processes for composites are the following:

Laser Cutting of Composites

Because composites are comprised of two or more different materials, choosing the proper laser wavelength(s) is critical. If all components of the composite are organic, they will all absorb the energy of a CO2 laser beam. The laser beam will heat the material directly in its path, causing it to vaporize. If the laser power is sufficiently high, the laser beam will cut completely through the material leaving a clean, smooth edge. If the components of the composite are metallic, the laser cutting process can be achieved with a Fiber laser. In many cases, the components of the composite will each require a different laser wavelength. This is addressed in ULS Advantages.

Laser Engraving of Composites

The power of the CO2 laser beam can be limited so that it removes (engraves) material to a specified depth. The laser engraving process can be used to create patterns and designs in the composite surface. Laser engraving can also be used to convey information.

Laser Marking of Composites

Many composites can be laser marked using a CO2 or Fiber laser beam. A CO2 laser should be used if the surface material is mostly organic. A Fiber laser should be used if the surface material is mostly metallic. In either case, the energy of the laser beam is absorbed by the surface of the composite causing its appearance to change. This creates a visible mark, without substantial material removal. Laser marking can be used to create designs or to convey information.

Combined Process

The laser cutting, engraving, and marking processes described above can be combined without having to move or re-fixture the composite.

General Composite Material Laser System Considerations

Platform Size – Must be large enough to hold the largest composites that will be laser processed or be equipped with Class 4 capability and safety precautions for processing larger sheets.

Wavelength – The 10.6 micron wavelength CO2 laser is the the best choice if the composite is composed mostly of organic materials. The 1.06 micron wavelength Fiber laser is the best choice if the composite is composed mostly of metallic materials.

Laser Power – Must be selected based on the processes that will be performed. 25 to 150 Watts (CO2 Laser) is best for laser cutting, engraving, and marking composites that are comprised mostly of organic materials. 40 to 50 Watts (Fiber laser) is best for laser cutting, engraving and marking composites that are comprised mostly of metallic materials.

Lens – A 2.0 lens is the best general process lens for composite laser material processing.

Cutting Table – Supports composites of plastic for laser cutting.

Exhaust – Must have sufficient flow to remove the gasses and particles that are generated during laser process from the composite laser engraving, cutting, and marking equipment.

Air Assist – Provides a jet of air near the focal point of the laser to help remove gasses and particles that are generated during composite laser engraving, cutting, and marking.

Environmental, Health and Safety Considerations for Composite Laser Material Processing

Laser-material interactions almost always create gaseous effluent and/or particles. The effluent will include various volatile organic compounds (VOCs) and should be routed to an exterior environment. Alternatively it may be treated with a filtration system first and then routed to an exterior environment. Composite combustion is inherent to laser processing and may produce flames. Therefore composite laser material processing should always be supervised.